Union Distillery Maltwhisky do Brasil Ltda is a company specialized in producing malt whisky.

Union Distillery was founded in 1948 under the name União Montanhesa de Indústrias and was pioneer in the production of beverages (wines and derivatives) in the municipality of Veranópolis, in the state of Rio Grande do Sul.

From 1972 onwards, with the change of shareholders, the focus of the business became the production of malt whisky and bottled beverages. The current corporate name was adopted in 1974.

In the late 1980s, the company began to sell only bulk bases for beverages and specialized in the production of its main product: malt whisky. Over the years, always attentive to developments, the company sought technical advice for the transfer of knowledge about the production of malt whisky and technological updates.

In mid-2015, Union Distillery put into operation a new distillery in the city of Bento Gonçalves, Rio Grande do Sul. The production process is certified by the ISO 22000 standard - food safety.

In 2023, the company also obtained Kosher certification for the products supplied to the bottling industries - Single Malt Alcoholic Distillate and Malt Whisky.

Our Business: “To produce malt whisky and signature whisky.”

Our Mission: “To develop, produce, and market malt whisky, providing knowledge through unique experiences in whisky consumption.”

Our Vision until 2030: "To be recognized in the market, through original products, developed in an innovative and sustainable way."

Integrated food quality and safety policy:

“Union Distillery’s quality is practiced on a daily basis, with an efficient team, adequate technology and continuous improvement; working in partnership with suppliers and in harmony with society and the environment; seeking results in accordance with our organizational guidelines and our strategic objectives. This set of actions allows us to satisfy the needs of our customers with products and services prepared within the legal requirements and the standards required by food safety.”

Products

The distillate is produced by processing a single cereal: malted barley, from selected varieties, peated or not, national and imported. In addition to malted barley, two other very important ingredients are needed for its production: water and yeast. After aging in American oak ex-bourbon barrels for at least 2 years, the product becomes known as malt whisky and can be used to produce whiskies.

Single malt alcoholic distillate

The new distillate (spirit/new make) is recommended for making mixed alcoholic drinks.

Malt whisky

Aging in oak barrels incorporates compounds extracted from the wood into the single malt alcoholic distillate, giving the drink a traditional characteristic, accentuating its color, aromas and flavors, increasing its complexity and making it ideal for producing pure malt whiskies and blended whiskies.

Peated Malt whisky

Malt whisky made from the distillation of peated malted barley is used to add smoky flavors and aromas to the drink (peaty and smoky notes - tar, embers, iodized, salt).

(Peat is a type of charcoal that is used to dry the barley during the malting process and whose smoke transfers characteristic flavors and aromas to the grain).

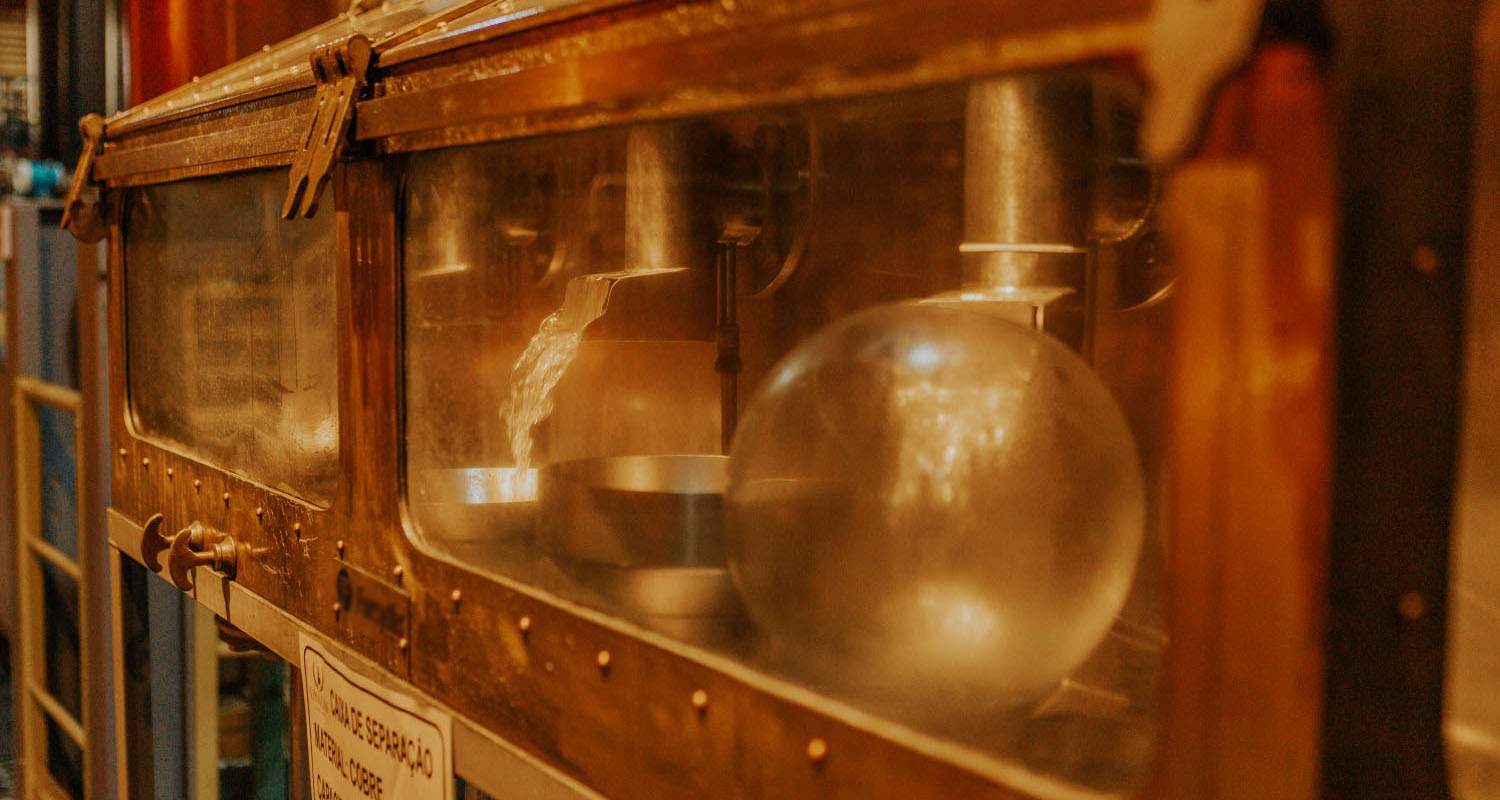

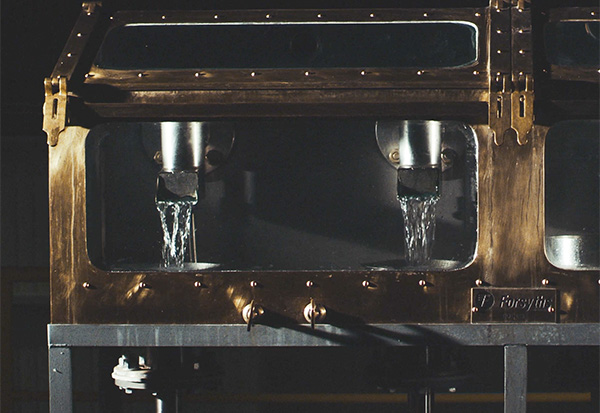

Get to know our process

Malt whisky distillation follows traditional processes, combining innovation and technology. With the knowledge accumulated over years of experience, standardized and certified processes, Union Distillery guarantees control, quality and credibility. Copper distillers, called pot stills, are used in the production process.

MILLING

Malted barley is crushed in a mill to facilitate the extraction of starch.

Rollers grind the grains to obtain a certain consistency of husk, medium and flour (grist).

SACCHARIFICATION

The ground grain (grist) is transferred to a stainless steel tank (mash tun) where the process known as “saccharification” takes place. During this process, hot water is passed through several times at controlled times and temperatures to produce the wort. At the same time, the enzymes present in the wort are activated and transform the starch into maltose (sugar) which will be fermented. At the end of the process, the processed barley is removed and used as animal feed.

FERMENTATION

The wort, at a stable temperature, is deposited in tanks where fermentation takes place. Yeasts/natural ferments are added, which act to transform the maltose into alcohol. This liquid (wash), after fermentation, is sent for distillation.

DISTILLATION

Distillation is the process that extracts alcohol from fermented wort, through heating and condensation. It is a process carried out in copper stills (pot stills) in a discontinuous manner (two stages):

- First distillation: the fermented wort is distilled to obtain a low alcohol content (low wine) that will be used in the second distillation;

- Second distillation: the liquid from the first distillation is distilled again and divided into head, body and tail. The body of the distillation is the product itself (spirit/new make) and will be barreled to become malt whisky.

AGING

The aging process is carried out in 200-liter oak barrels. The main factors that influence the aging process are:

- type of wood;

- storage conditions;

- climate - temperature and humidity;

- aging time.

These factors give malt whisky its own organoleptic characteristics, such as: color, flavor and aromas.

PROCESS REPRESENTATION

GALERY

Contact

Where to find us:

Veranópolis

Bento Gonçalves